Tungsten carbide burrs for high-performance applications

High capacity burrs

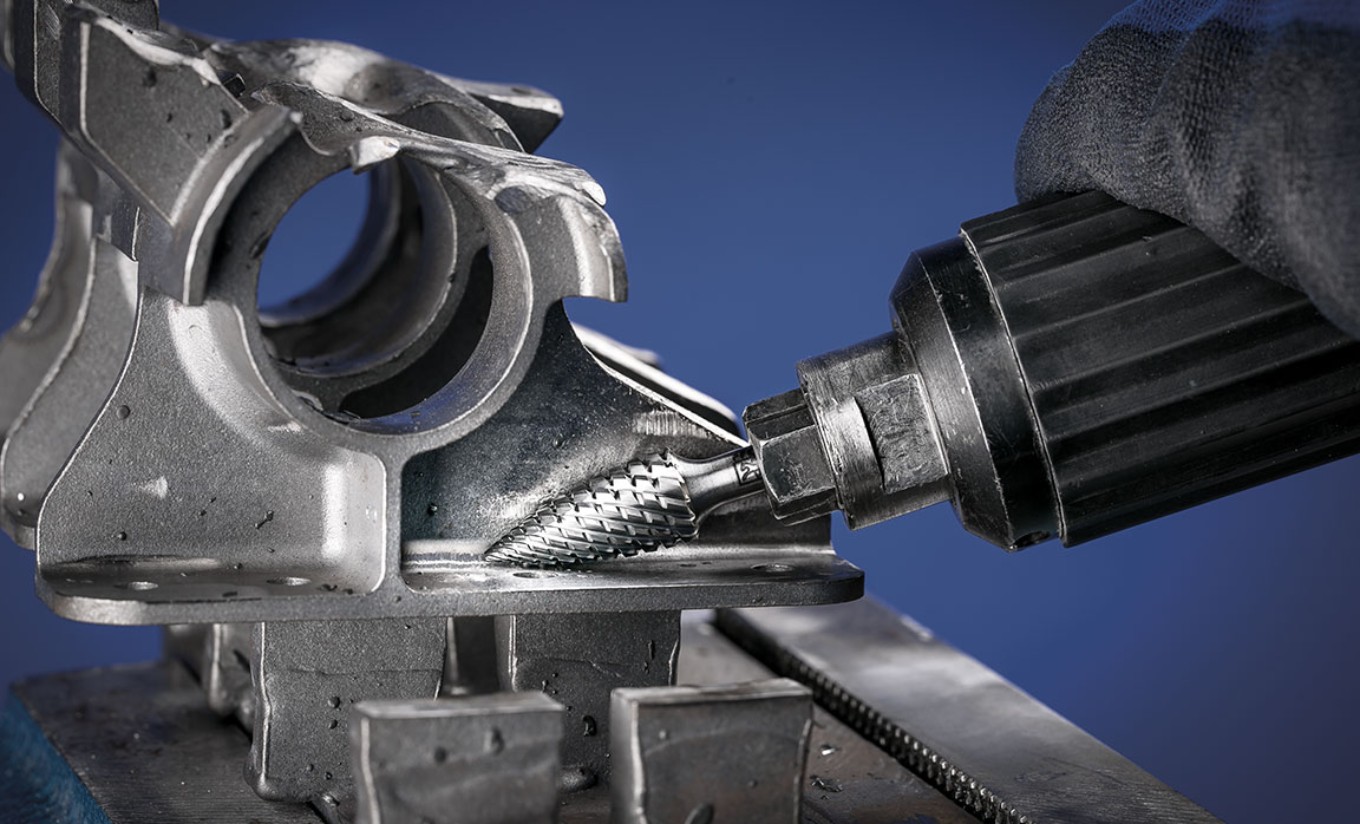

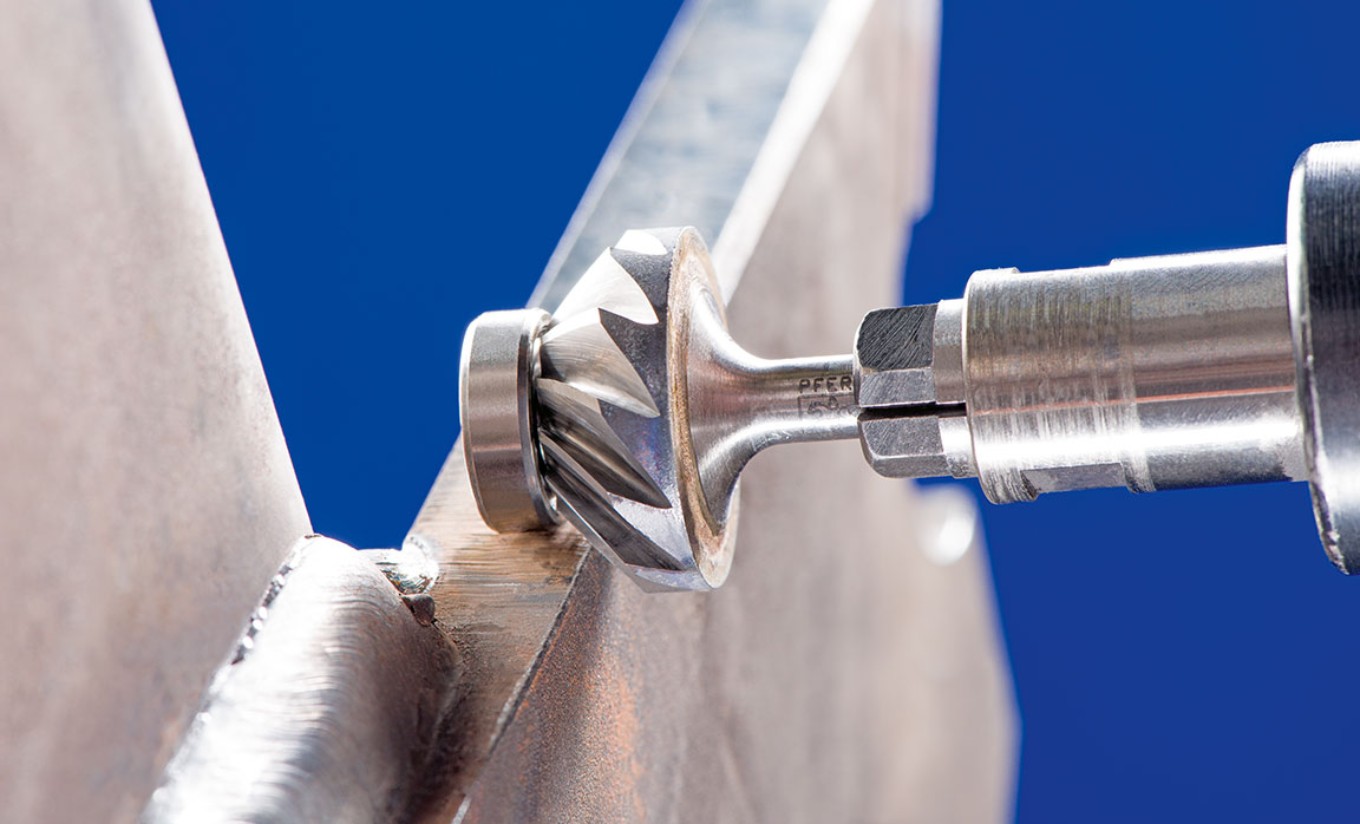

Tungsten carbide burrs for high-performance applications are distinguished by their material or application-specific design, guaranteeing an optimal stock removal rate and high aggressiveness at the same time as good guidability.

TC burrs for high-performance applications are a convincing offering due to their significant time savings and high profitability compared with conventional burrs.

The highly accurate concentricity enables impactfree working without creating chatter marks. The result: considerably reduced wear on the tool and tool drive. The high-performance burrs are also available with a HICOAT coating.

Advantages:

- Optimum stock removal rate, high aggressiveness, and good guidance.

- High economic efficiency compared with conventional burrs.

- The highly accurate concentricity enables impactfree working without creating chatter marks.

- Significant time savings.

- Also available with a high-quality HICOAT coating.

PFERD high-performance burrs are based on an innovative and sophisticated system for working on surfaces. The tungsten carbide burrs from our high-performance line offer quick and efficient solutions for a wide range of materials and application areas.

Download

Material-specific tungsten carbide burrs

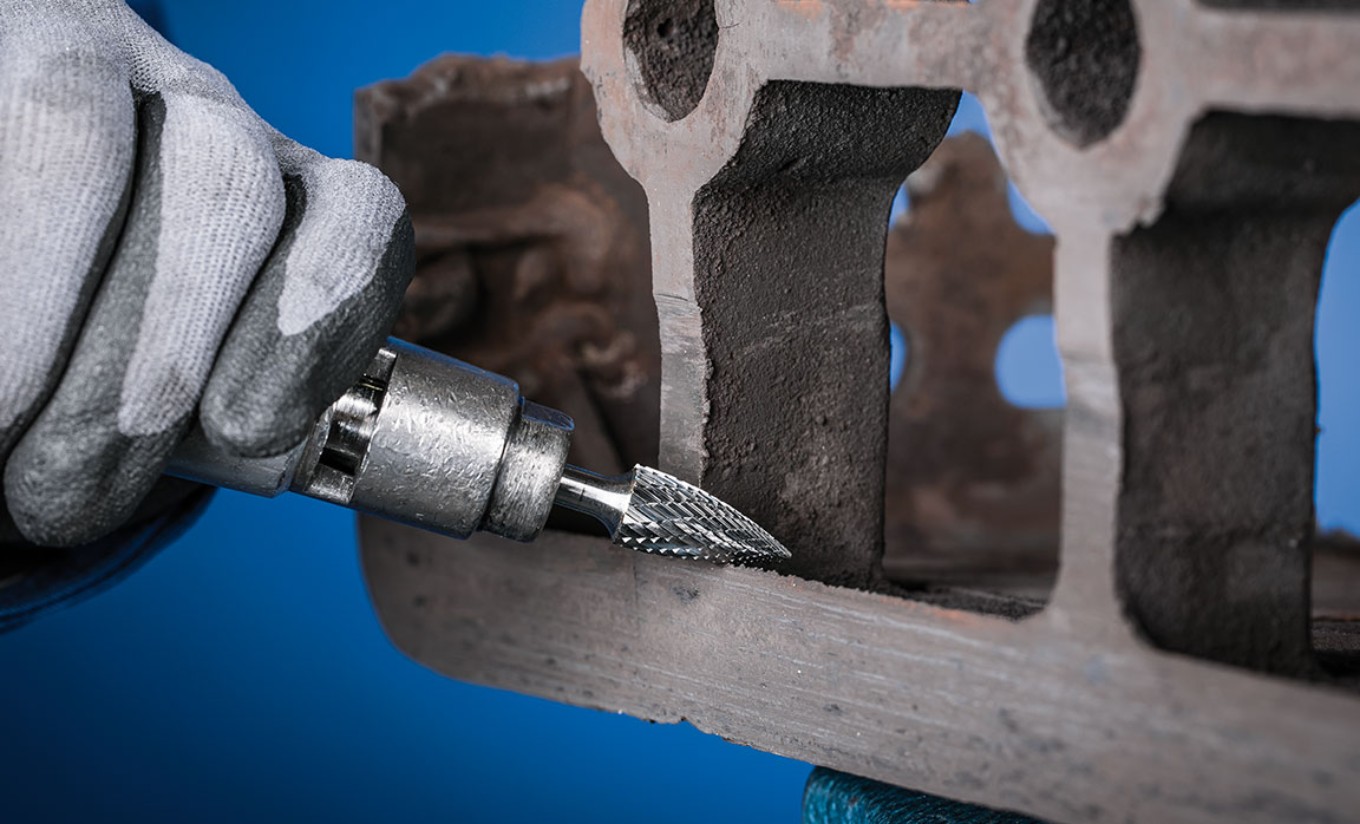

The material-specific tungsten carbide burrs by PFERD enable maximum stock removal on a wide range of materials. PFERD has developed a different cut for the various different materials.

The user-friendly product designations make it easier to find the right cut for the material that the user wants to work on.

Material-specific tungsten carbide burrs are available in the following cuts:

Advantages:

- Maximum stock removal thanks to specially designed cut.

- User-friendly product designations.

Application-specific tungsten carbide burrs

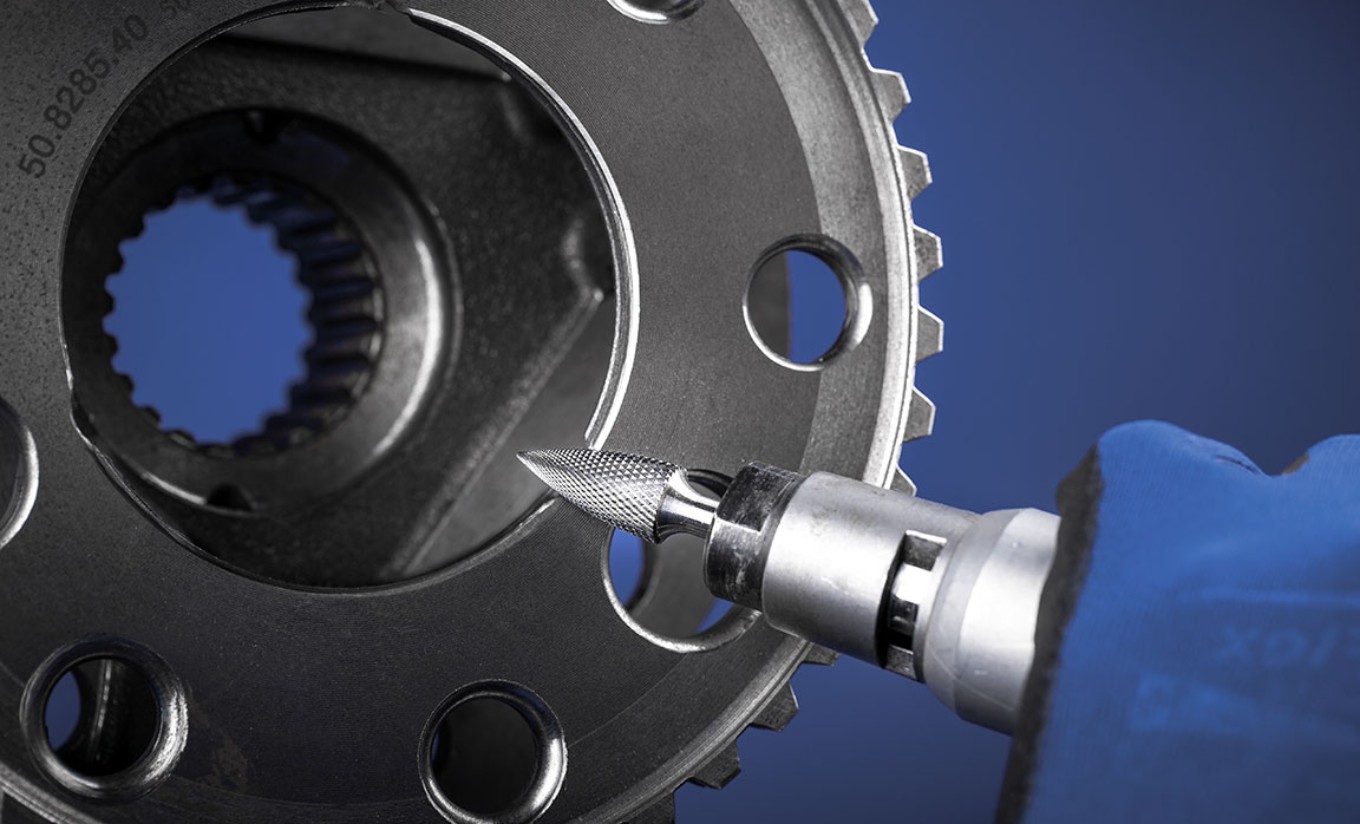

The application-specific tungsten carbide burrs by PFERD enable maximum stock removal for a wide variety of applications.

Users in diverse sectors rely on PFERD’s high-performance burrs for milling out, levelling, deburring or working on weld seams.

No matter whether for tough applications, finishing, or defined work on edges: PFERD has the perfect solution for your applications.

Application-specific tungsten carbide burrs from our high-performance line are available in the following cuts, among others:

Advantages:

- Maximum stock removal thanks to specially designed cut.

- The perfect cut for any application.