TC burrs - STEEL cut

With the innovative STEEL cut, PFERD TOOLS has developed unique burrs for working with steel and cast steel. They are characterized by significantly increased aggressiveness and good guidance.

Thus they ensure safe and precise work. The extremely high stock removal rate makes burrs with the STEEL cut impressive, with significant time savings and a high economic value.

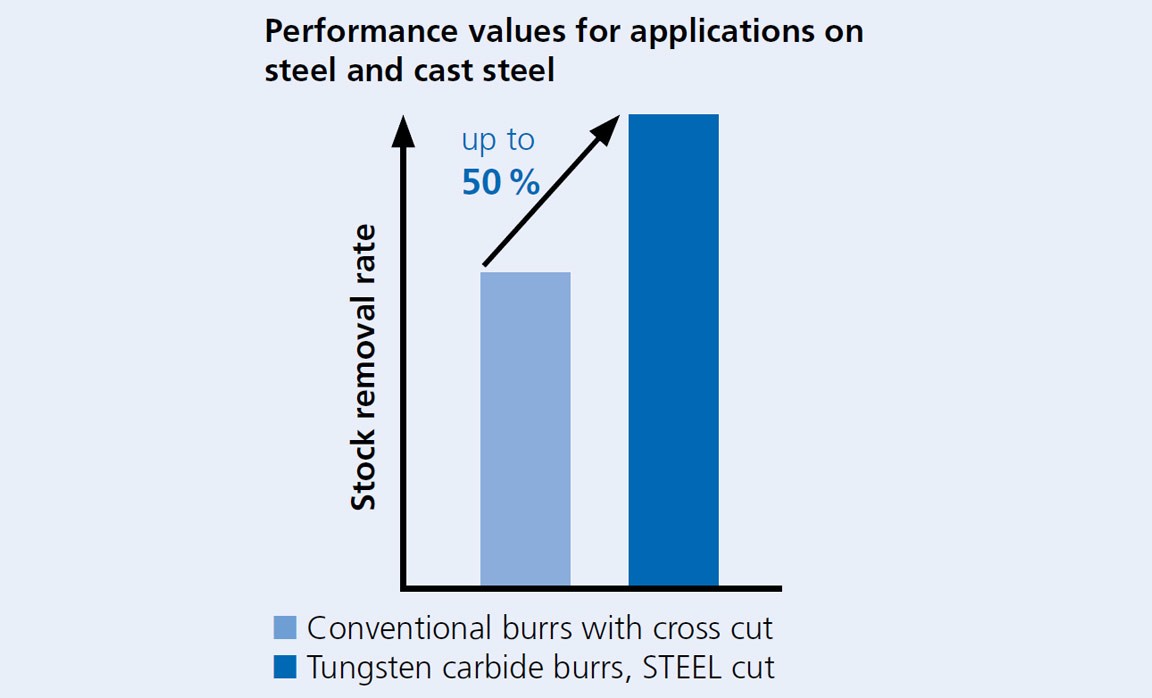

In comparison to conventional cross-cut burrs, the STEEL cut is characterized by up to 50 % higher stock removal rate when used on steel and cast steel.

Advantages:

- Up to 50 % higher stock removal rate when used on steel and cast steel in comparison to conventional cross-cut burrs.

- Significantly increased aggressiveness, large chips and very good chip removal through the innovative tooth geometry.

- Workpiece is protected through much lower thermal load.

- Reduced wear on the tool drive due to impact-free work without chatter marks, thanks to the high concentricity.

Materials that can be worked:

- Steel

- Cast steel

Applications:

- Milling out

- Levelling

- Deburring

- Cutting out holes

- Surface work

- Work on weld seams

Matching tool drives:

- Flexible shaft drive

- Straight grinder

- Robot

- Machine tools

Recommendations for use:

- If possible, use the tools on powerful drives with elastically mounted spindles to avoid vibration.

- For the cost-effective use of burrs, work with higher rotational/cutting speeds.

- Power recommendation for tool drives: from 300 watts.

- Please observe the rotational speed recommendations.

Safety note:

The very high stock removal rate can cause discolouration on the shank. This does not constitute a safety risk.