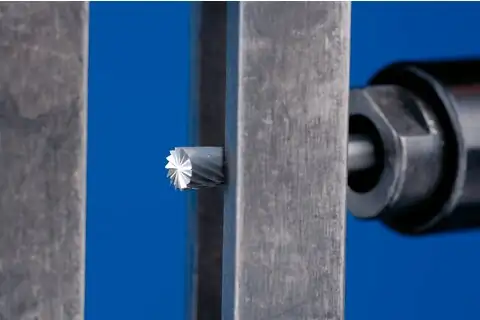

Tungsten carbide burrs for general use, cut 3 PLUS, inverted cone WKN without end cut

Tungsten carbide inverted cone WKN dia. 06x07 mm shank dia. 3 mm Z3P universal medium cross cut

WKN 0607/3 Z3 PLUS

Technical information

Tungsten carbide inverted cone WKN dia. 06x07 mm shank dia. 3 mm Z3P universal medium cross cut

- Angle

- 10 °

- Cut

- 3 PLUS

- Dia. external

- 6 mm

- Dia. shank

- 3 mm

- Length, cut

- 7 mm

- Length, total

- 37 mm

- RPM, grey cast iron, white cast iron

- 24000 - 32000 RPM

- RPM, hard non-ferrous metals

- 13000

- RPM, hardened, heat-treated steels over 1,200 N/mm²

- 13000 - 19000 RPM

- RPM, high-temperature-resistant materials

- 13000 - 24000 RPM

- RPM, rust and acid-resistant steels

- 13000 - 19000 RPM

- RPM, steels up to 1,200 N/mm²

- 24000 - 32000 RPM

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

- Materials that can be worked

- Applications

- Drive types